| نموذج | SLDM168-5 | SLDM168-6 | SLDM168-7 | SLDM168-8 | SLDM168-9 |

| حجم الهواء (10^4 م³/ساعة) | 9.6 ~ 12.0 | 11.52 ~ 14.4 | 13.44 ~ 16.8 | 15.36 ~ 19.2 | 17.28 ~ 21.6 |

| إجمالي مساحة التصفية (م²) | 2000 | 2400 | 2800 | 3200 | 3600 |

| غيغاواط. (ر) | 50 | 60 | 70 | 80 | 90 |

| غرفة | 5 | 6 | 7 | 8 | 9 |

| كمية كيس الفلتر | 840 | 1008 | 1176 | 1344 | 1512 |

| المقاومة (باسكال) | 1200 ~ 1600 | ||||

| استهلاك الهواء (م³/دقيقة) | 2 ~ 4 | ||||

| كثافة التفريغ (ملجم / ن م³) | أقل من 50 | ||||

| تسرب الهواء (٪) | أقل من 3 | ||||

| ضغط | 0.2~0.4 | ||||

تحديد

يوجد 32، 64، 96 و128 نوعًا من أكياس الترشيح في كل غرفة. قطر كيس الفلتر 130 ملم، وطول كيس الفلتر 2450 ملم و3600 ملم

مميزة

تتميز طريقة التنظيف خارج الخط بمزايا طاقة التنظيف الكبيرة وتأثير التنظيف الجيد ومقاومة النظام المنخفضة وعمر الخدمة الطويل لحقيبة الفلتر وكفاءة إزالة الغبار العالية

طلب

مناسبة لإزالة الغبار عالي التركيز. يصل تركيز الغبار لغاز المدخل إلى 1000 جم/نيوتن متر مكعب. وهو مناسب لإزالة غبار غاز المداخن في المعادن ومواد البناء والآلات والصناعات الكيماوية والطاقة الكهربائية والصناعات الخفيفة وغيرها من الصناعات.

مقدمة

1. يستخدم مجمع الغبار ذو الكيس النبضي تقنية التنظيف النفاث النبضي، والتي تتمتع بقدرة تنظيف قوية، وكفاءة عالية في إزالة الغبار، وتركيز منخفض للانبعاثات، ومعدل تسرب هواء منخفض، واستهلاك منخفض للطاقة، وبصمة صغيرة، وتشغيل مستقر وموثوق، وفوائد اقتصادية جيدة.

2. جسم الصندوق يعتمد تصميم محكم، أداء إغلاق جيد، وباب الفحص يستخدم مواد إغلاق ممتازة. يتم استخدام الديزل للاختبار أثناء عملية الإنتاج، ومعدل تسرب الهواء منخفض.

3. تم ترتيب قناة الهواء المخرج بشكل مضغوط مع مقاومة منخفضة لتدفق الهواء.

4. يتم اعتماد التنظيف النفاث النبضي مع إيقاف هواء الغرفة، مع دورة تنظيف طويلة واستهلاك منخفض، مما يمكن أن يضاعف عمر كيس الفلتر ولوحة الصمام.

5. يمكن تحقيق استبدال الكيس دون إيقاف الآلة، ولا تؤثر الصيانة على التشغيل العادي للمعدات.

6. تم اعتماد طريقة استخراج الكيس العلوي لتحسين بيئة عملية الصيانة.

حدود

| المعلمة التقنية | نموذج | ||||||||||

| SLDM160-2*5 | SLDM160-2*6 | SLDM160-2*7 | SLDM160-2*8 | SLDM160-2*9 | SLDM176-2*5 | SLDM176-2*6 | SLDM176-2*7 | SLDM176-2*8 | SLDM176-2*9 | ||

| حجم الهواء (م³/ساعة) | 23.04 ~ 28.8 | 27.65 ~ 34.56 | 32.5 ~ 40.32 | 36.86 ~ 28.8 | 41.47~51.84 | 25.34 ~ 31.84 | 30.41 ~ 38.02 | 35.48 ~ 44.35 | 40.55~50.68 | 45.62~57.02 | |

| إجمالي مساحة التصفية (م²) | 4800 | 5760 | 6720 | 7680 | 8640 | 5305 | 6336 | 7392 | 8448 | 9504 | |

| ز. الوزن (ر) | 138 | 165 | 193 | 220 | 248 | 150 | 180 | 210 | 240 | 270 | |

| غرفة (قطعة) | 10 | 12 | 14 | 16 | 18 | 10 | 12 | 14 | 16 | 18 | |

| حقيبة التصفية | الكمية (جهاز كمبيوتر شخصى) | 1600 | 1920 | 2240 | 2560 | 2880 | 1760 | 2112 | 2464 | 2186 | 3186 |

| المواصفات (بوصة) | F160*6000 | ||||||||||

| صمام النبض | الكمية (جهاز كمبيوتر شخصى) | 100 | 120 | 140 | 160 | 180 | 110 | 132 | 154 | 176 | 198 |

| المقاومة (باسكال) | ≥1500 | ||||||||||

| تصفية سرعة الرياح (م / ميل) | إذا كان المستخدم يحتاج، وفقا لحالة معينة أقل أو أعلى | ||||||||||

| تركيز المدخل (جم/ن م³) | ≥100 | ||||||||||

| معدل تسرب الهواء (٪) | ≥3 | ||||||||||

| الضغط (ميغاباسكال) | 0.3~0.5 | ||||||||||

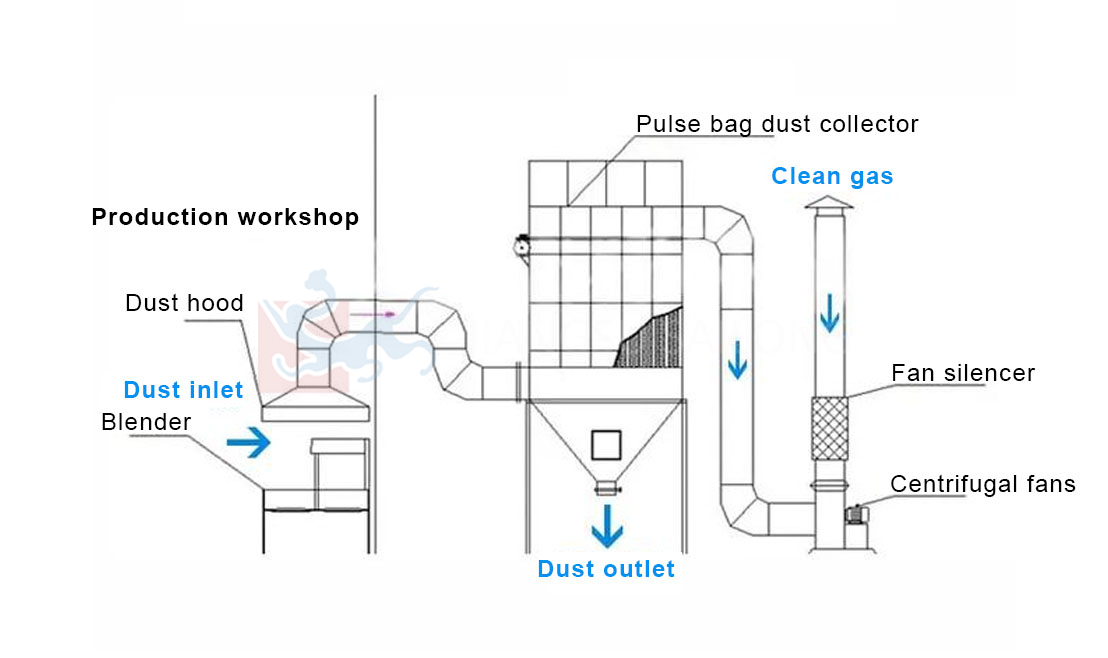

إن مجمع الغبار ذو كيس الهواء النبضي عبارة عن معدات إزالة الغبار الصناعية ذات الكفاءة العالية. وفيما يلي مقدمة تفصيلية عنه:

التركيب الهيكلي

• جزء الصدفة:

بما في ذلك الغرفة النظيفة (صندوق تنقية الغاز)، وغرفة الترشيح، وقسم المقصورة، وباب الفحص وهيكل القشرة. تم تجهيز الغرفة النظيفة بصمامات رفع وألواح زهور وأنابيب رش قصيرة وما إلى ذلك؛ تم تجهيز غرفة الترشيح بأكياس الفلتر وإطاراتها لدعم وتثبيت أكياس الفلتر لضمان عملية ترشيح سلسة للغاز المحتوي على الغبار.

• آلية تفريغ قادوس الرماد والرماد:

يتم استخدام قادوس الرماد لجمع الغبار المفلتر. وفقًا للسلسلة المختلفة وتركيز الغبار المستورد، يمكن إعداد أجهزة تفريغ الرماد مثل الناقلات اللولبية ومزالق نقل الهواء ومفرغات المكره الصلبة (صمامات تفريغ الرماد) على التوالي لتفريغ الغبار المجمع في الوقت المناسب.

• صندوق هواء مدخل ومخرج:

بما في ذلك مجاري الهواء مدخل ومخرج والأقسام الوسطى. يتم ترتيب هيكل الصف الواحد (أو الصف الواحد) على جانب واحد من الصدفة، ويتم ترتيب هيكل الصف المزدوج (أو الصف المزدوج) في منتصف الصدفة؛ بالنسبة للسلسلة الأصغر حجمًا 32، لا يوجد صندوق منفصل، ويتم توصيل قنوات هواء المدخل والمخرج بقادوس الرماد والغرفة النظيفة على التوالي.

• جهاز تنظيف النبض:

يتكون من صمام نبضي وكيس هوائي وأسطوانة لصمام الرفع وصمام الملف اللولبي الخاص به. يعد صمام النبض مكونًا رئيسيًا للتنظيف. يتحكم في نفخ الهواء المضغوط لتنظيف كيس الفلتر. يتم استخدام كيس الهواء لتخزين الهواء المضغوط وتوفير مصدر هواء ثابت لصمام النبض. يتم استخدام صمام الرفع للتحكم في تبديل حالة الترشيح والتنظيف لكل غرفة.

• خطوط أنابيب الهواء المضغوط والأجهزة المساعدة:

بما في ذلك خط أنابيب الهواء المضغوط وجهاز تقليل الضغط، وفاصل الزيت عن الماء، ورذاذ الزيت، وما إلى ذلك. يتم استخدام فاصل الزيت عن الماء لفصل الزيت والماء في الهواء المضغوط لمنع تلف المعدات؛ يمكن لضباب الزيت أن يوفر تشحيمًا للأجزاء المتحركة للمعدات.

• مبدأ العمل:

يدخل الغاز المحتوي على الغبار إلى قادوس مجمع الغبار من مدخل الهواء. تسقط جزيئات الغبار الكبيرة مباشرة في القادوس بسبب الاصطدام بالقصور الذاتي، والترسيب الطبيعي، وما إلى ذلك. يتم توزيع الغاز المحتوي على الغبار الناعم بالتساوي من خلال لوحة التوجيه ويدخل إلى كيس الفلتر لكل غرفة. عندما يمر الغاز عبر كيس الفلتر، يتم الاحتفاظ بالغبار على السطح الخارجي لكيس الفلتر. يدخل الغاز المنقى إلى الصندوق من خلال كيس الفلتر ويتم تفريغه في الغلاف الجوي من خلال فتحة لوحة الصمام ومخرج الهواء. مع استمرار أعمال الترشيح، يستمر الغبار الموجود على السطح الخارجي لحقيبة الفلتر في الزيادة، وتزداد مقاومة تشغيل مجمع الغبار. عندما تصل المقاومة إلى القيمة المحددة مسبقًا، ترسل وحدة التحكم في تنظيف الغبار إشارة، للتحكم أولاً في صمام الرفع لإغلاق فتحة لوحة الصمام، وقطع تدفق هواء الترشيح للغرفة، وإيقاف عمل الترشيح للغرفة. بعد ذلك، يتم فتح صمام النبض، ويتم دفع الهواء المضغوط الذي يزيد عن 0.4MPa إلى غرفة الهواء النظيف. يتوسع الهواء المضغوط بسرعة في جسم الصندوق ويندفع إلى كيس الفلتر، مما يتسبب في تشوه كيس الفلتر واهتزازه. مع تأثير تدفق الهواء العكسي، تتم إزالة الغبار الموجود على السطح الخارجي لكيس الفلتر ويسقط في قادوس الرماد. بعد الانتهاء من تنظيف الغبار، يتم فتح صمام الرفع مرة أخرى، وتعود الحجرة إلى حالة عمل الترشيح. بهذه الطريقة، يتم عزل كل حجرة ويتم إجراء عملية تنظيف الغبار على التوالي.

المزايا والخصائص

• كفاءة عالية في إزالة الغبار:

يمكن أن تصل إلى أكثر من 99.9%، ويمكنها إزالة جزيئات الغبار الدقيقة بشكل فعال، ويمكن التحكم في انبعاثات الغبار أقل من 30 ملجم/نيوتن متر مكعب، مما يلبي متطلبات حماية البيئة الصارمة.

• حجم هواء كبير:

يمكن لهيكل مدخل الهواء ذو المقطع العرضي الكبير التعامل مع كميات كبيرة من الهواء من الغاز المغبر، وهو مناسب لمواقع الإنتاج الصناعي ذات الأحجام المختلفة.

• يمكنه التعامل مع الغبار عالي التركيز:

بالنسبة للغاز المحتوي على غبار عالي التركيز أقل من 100 جم/نيوتن متر مكعب، لا يزال بإمكانه الحفاظ على تأثير جيد لإزالة الغبار، والتغلب على مشكلة انخفاض كفاءة بعض مجمعات الغبار عند التعامل مع الغبار عالي التركيز.

• تأثير تنظيف جيد:

تتميز طريقة التنظيف الفريدة لغرفة الصندوق الفرعي بقوة تنظيف قوية وموحدة، والتي يمكنها إزالة الغبار تمامًا من كيس الفلتر، وتجنب الامتزاز الثانوي وتراكم الغبار، وضمان أداء الترشيح المستقر على المدى الطويل لكيس الفلتر، وإطالة عمر خدمة كيس الفلتر.

• التصميم الهيكلي المعقول:

منطقة تصفية حجم الوحدة كبيرة، وحجم المعدات صغير نسبيًا، ومساحة الأرضية صغيرة. وقوة الصدفة جيدة، يمكنها تحمل الضغط والاهتزاز الكبير، والعملية مستقرة وموثوقة.

• درجة عالية من الأتمتة:

مجهزة بجهاز التحكم في التنظيف المتقدم، يمكنها تحقيق التوقيت أو التنظيف بمقاومة ثابتة، وتشغيل بسيط ومريح، وتقليل عبء العمل وتكلفة الصيانة للتشغيل اليدوي.

• مجموعة واسعة من التطبيقات:

يستخدم على نطاق واسع في تكسير مصانع الأسمنت والتعبئة وسقف التخزين ومبرد الكلنكر ومطاحن مختلفة وأنظمة جمع الغبار الأخرى، بالإضافة إلى المعادن والصناعات الكيماوية والآلات والغلايات المدنية وغيرها من جمع غبار غاز النفايات.

• انخفاض استهلاك الطاقة التشغيلية:

أثناء التشغيل، يكون استهلاك الطاقة منخفضًا، مما يمكن أن يقلل بشكل فعال من تكلفة الإنتاج للمؤسسة ويلبي متطلبات الحفاظ على الطاقة وخفض الانبعاثات.

حدود

| المعلمة التقنية | نموذج | ||||||||||

| SLDM160-2*5 | SLDM160-2*6 | SLDM160-2*7 | SLDM160-2*8 | SLDM160-2*9 | SLDM176-2*5 | SLDM176-2*6 | SLDM176-2*7 | SLDM176-2*8 | SLDM176-2*9 | ||

| حجم الهواء (م³/ساعة) | 23.04 ~ 28.8 | 27.65 ~ 34.56 | 32.5 ~ 40.32 | 36.86 ~ 28.8 | 41.47~51.84 | 25.34 ~ 31.84 | 30.41 ~ 38.02 | 35.48 ~ 44.35 | 40.55~50.68 | 45.62~57.02 | |

| إجمالي مساحة التصفية (م²) | 4800 | 5760 | 6720 | 7680 | 8640 | 5305 | 6336 | 7392 | 8448 | 9504 | |

| ز. الوزن (ر) | 138 | 165 | 193 | 220 | 248 | 150 | 180 | 210 | 240 | 270 | |

| غرفة (قطعة) | 10 | 12 | 14 | 16 | 18 | 10 | 12 | 14 | 16 | 18 | |

| حقيبة التصفية | الكمية (جهاز كمبيوتر شخصى) | 1600 | 1920 | 2240 | 2560 | 2880 | 1760 | 2112 | 2464 | 2186 | 3186 |

| المواصفات (بوصة) | F160*6000 | ||||||||||

| صمام النبض | الكمية (جهاز كمبيوتر شخصى) | 100 | 120 | 140 | 160 | 180 | 110 | 132 | 154 | 176 | 198 |

| المقاومة (باسكال) | ≥1500 | ||||||||||

| تصفية سرعة الرياح (م / ميل) | إذا كان المستخدم يحتاج، وفقا لحالة معينة أقل أو أعلى | ||||||||||

| تركيز المدخل (جم/ن م³) | ≥100 | ||||||||||

| معدل تسرب الهواء (٪) | ≥3 | ||||||||||

| الضغط (ميغاباسكال) | 0.3~0.5 | ||||||||||

RELATED

RELATED

يستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.